The addition of a thread at the end of a tube can be costly, both from process and procurement points-of-view. Secondary operations are often also required to improve the finish of the assembly.

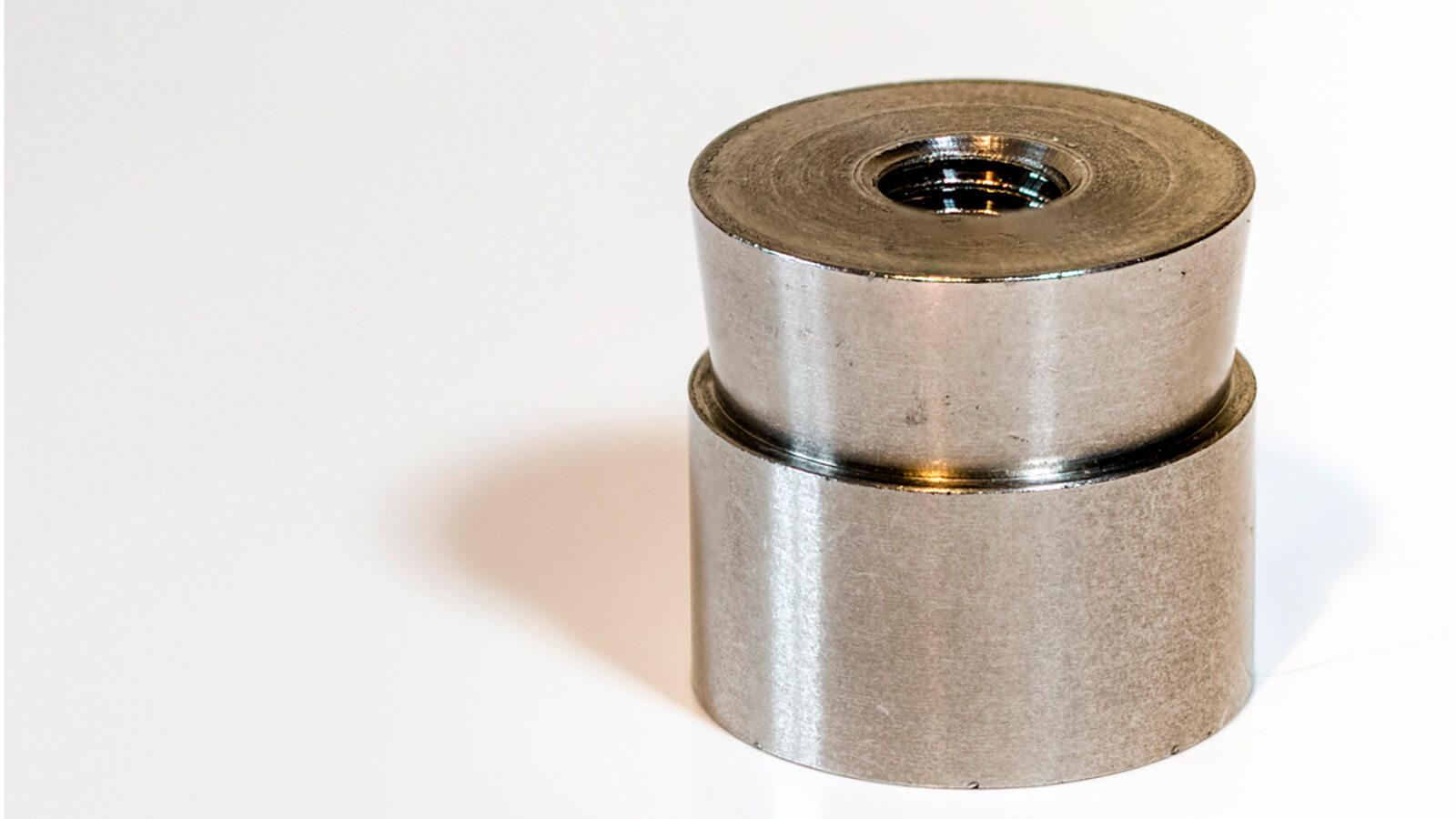

Discover how ENDFIX simplifies the processing and improves the overall product.