Our quality system is fully integrated into our management and management system.

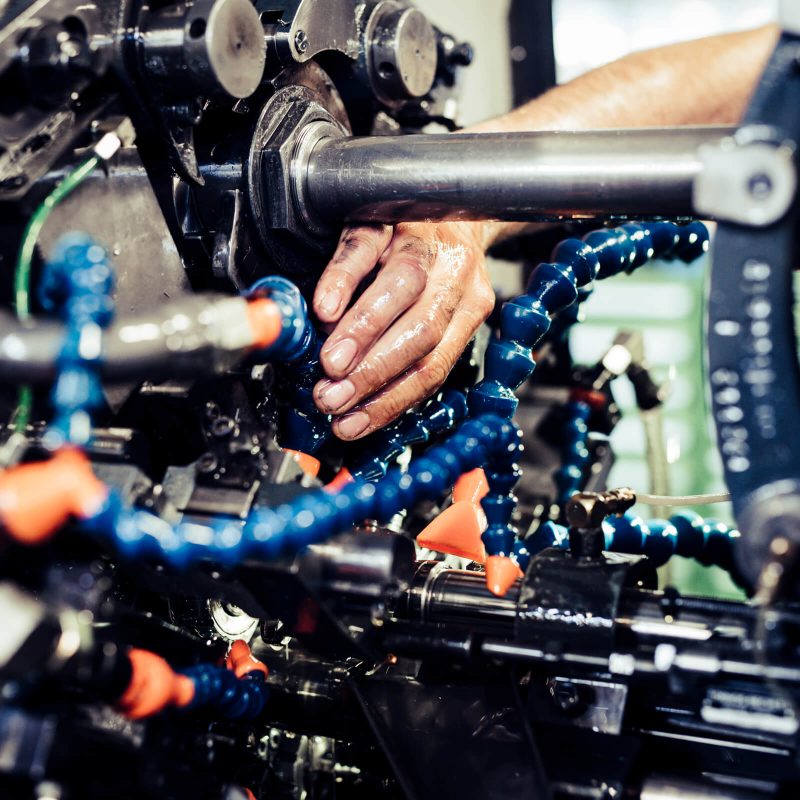

It includes the quality of the products, as well as the safety of the personnel.

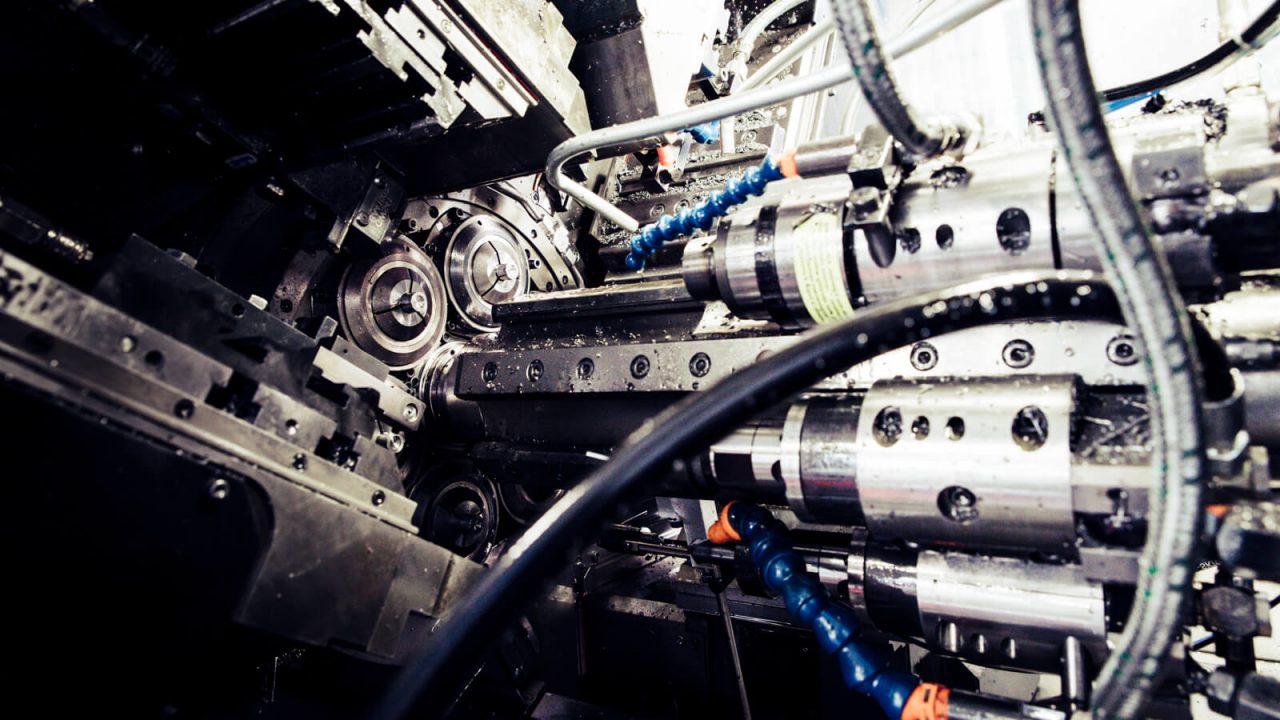

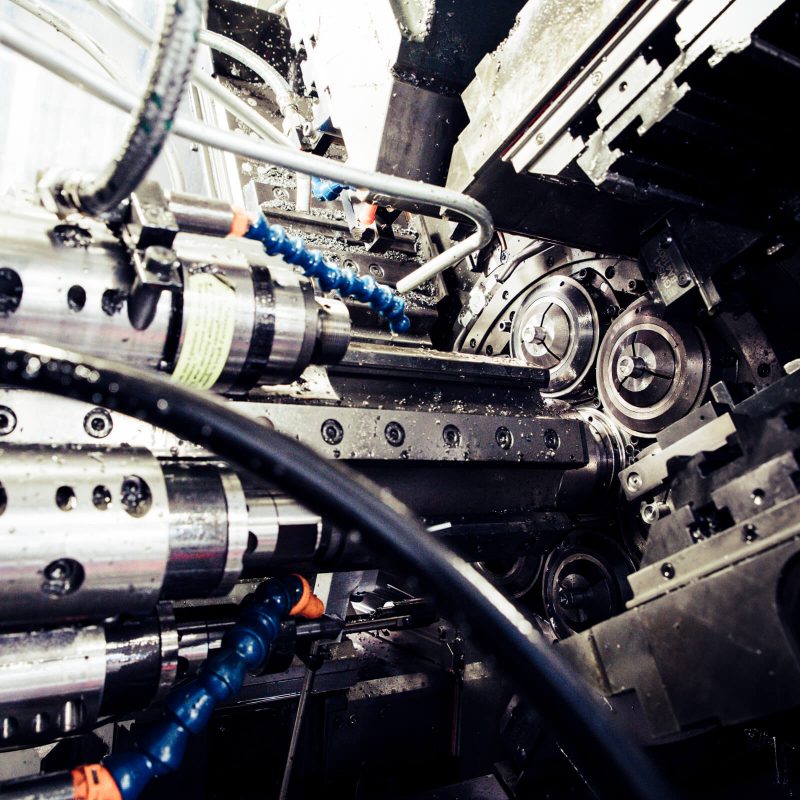

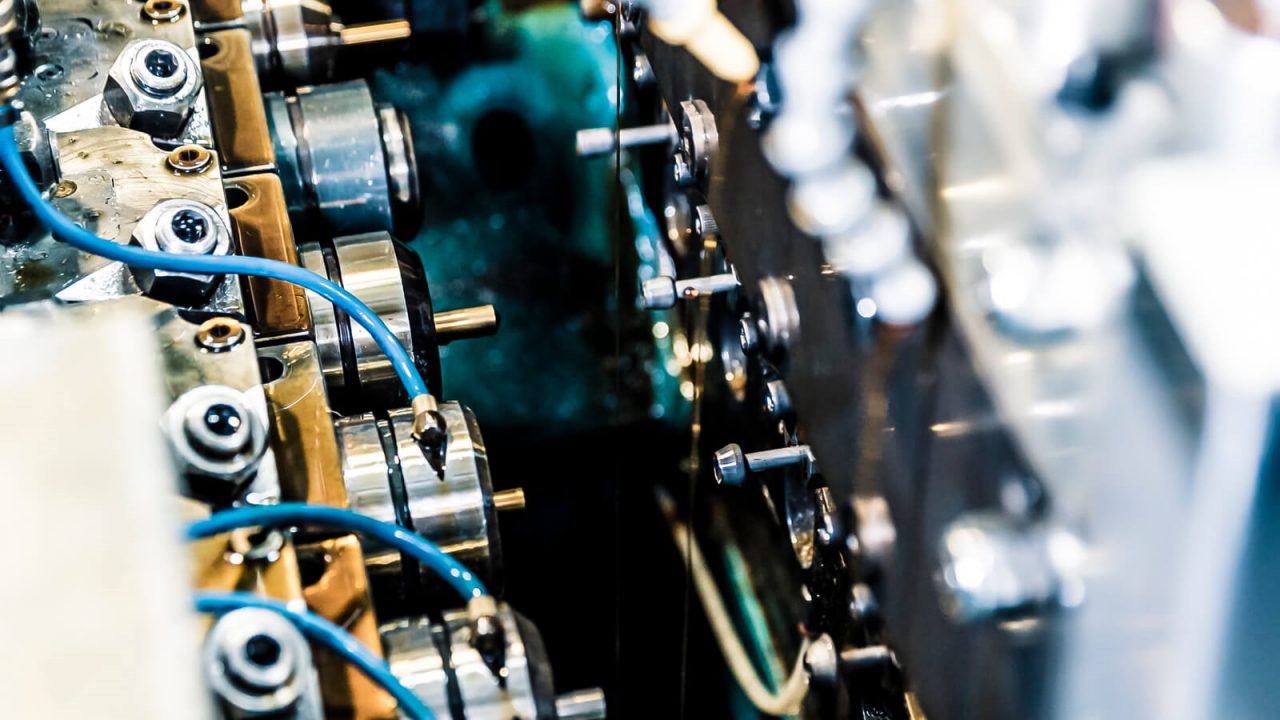

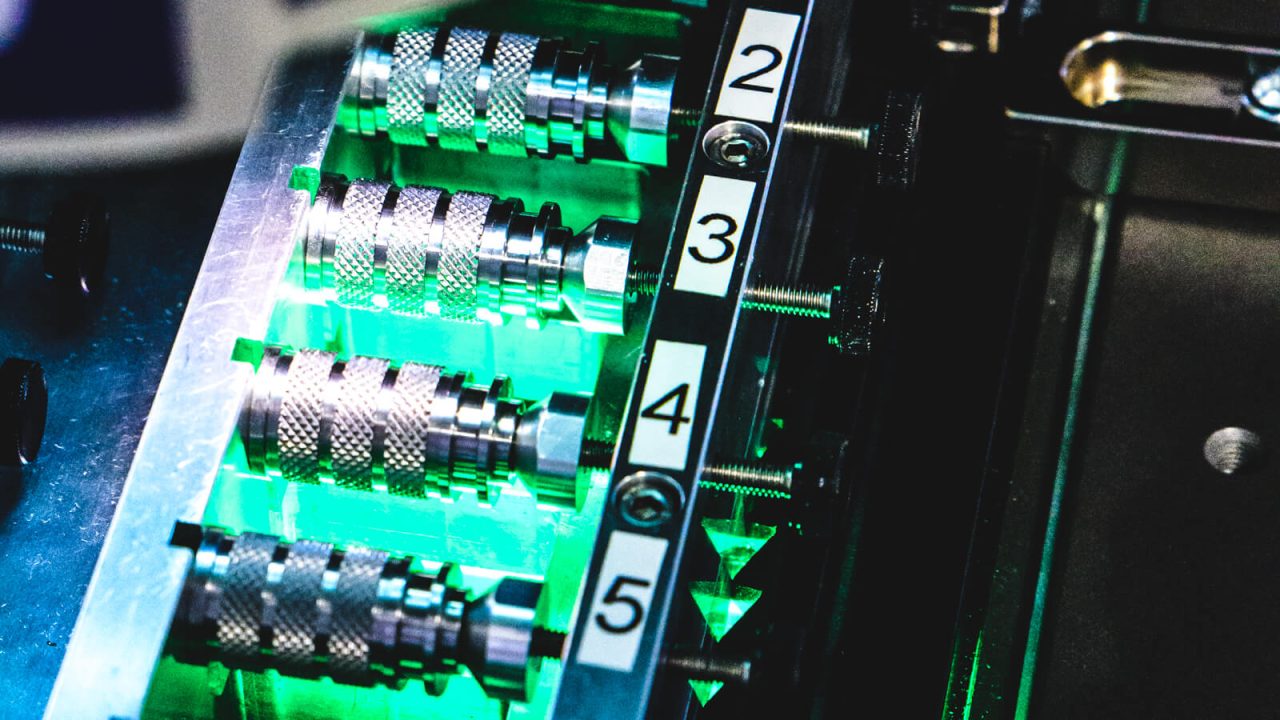

To guarantee the quality of our production, we are equipped with the latest control equipment (contactless optical measuring machine, Leitech gauge …).

Technical ranges, control ranges and monitoring of production are followed and guaranteed. The traceability is thus total and permanent from the order to the delivery.

Our quality team control and validate staff skills, product compliance, compliance with safety standards and company standards through post audits, manufacturing process audits and product audits.